Comb Back Rocker Class

by Elia Bizzarri | Jul 20, 2017 | 0 Comments

Comb back rocker

I have added a Comb Back Rocker class to my schedule, May 14-19, 2018. It is open to returning students only, since the spindles and bends will have to be made at home. This is the first time I have taught this chair in a group setting and I think it will be a fun class. More info on my teaching page.

Chair Stories: The Hardwood Forest

by Elia Bizzarri | Jul 5, 2017 | 0 Comments

I first heard it today, as I was turning legs for a set of four Loop Back side chairs. The lathe is all you hear when it’s running. Yet each time I turned it off, the sound was closer. Finally, I looked up from my lathe. There the beast was, along the back side of my property line, eating trees like so many match-sticks. A mechanical tree harvester.

I first heard it today, as I was turning legs for a set of four Loop Back side chairs. The lathe is all you hear when it’s running. Yet each time I turned it off, the sound was closer. Finally, I looked up from my lathe. There the beast was, along the back side of my property line, eating trees like so many match-sticks. A mechanical tree harvester.

As a kid in the woods, I’d seen them before. It mesmerized me: two huge arms grabbing a tall oak in a bear hug. The huge circular saw cuts the tree, then carries it around vertically like some oversized Christmas Tree on a Macy’s float. read more…

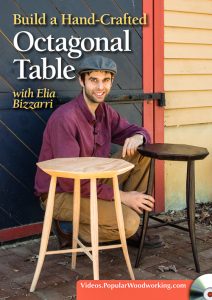

Octagonal Tables/Continuous Arm Class

by Elia Bizzarri | Jun 25, 2017 | 0 Comments

My new DVD is out! I love building these little tables – they have many of the fun aspects of building a chair, but they can be made in a weekend. Well, maybe two weekends, a month apart. Here’s a tour of my shop that the crew filmed while they were here: read more…

Storing Green Wood

by Elia Bizzarri | Jun 18, 2017 | 0 Comments

Photo by Josh Farnsworth

You’ve got your hands on some green wood. How do you store it?

If your winter stays below 40 or 50 degrees, take your time, it will probably keep fresh till spring. However, with several recent warm winters, rot seems to be becoming a year round event here in the Carolina Piedmont. read more…

Casting Bells

by Elia Bizzarri | Jun 8, 2017 | 0 Comments

This video has nothing to do with woodworking and it is in German, yet it is one of the most memorable craft videos I have ever watched.

Casting giant church bells. It starts with hand building 8′ tall molds made of brick and layers of mortar, fiber and metal. Really there’s two molds for each bell, a positive mold and a negative mold. The molds are only used once. Molds for a dozen bells are constructed in the bottom of a huge pit in the shop floor, then the pit is filled with sand. read more…

Octagonal Legs

by Elia Bizzarri | May 23, 2017 | 0 Comments

A couple months ago I filmed an Octagonal Side Table DVD and a Milk Painting DVD with Popular Woodworking. They should be out sometime this summer. Here’s a photo of the table:

To film a DVD you need lots of parts at various stages, so I made a pile of bent octagonal legs one morning:

10:03AM read more…

10:03AM read more…

Making Shellac

by Elia Bizzarri | May 10, 2017 | 0 Comments

This video was made by the fellow I buy my shellac flakes from. Who knew it took so much effort by insect and man to make a pound of shellac? Or that different trees make different kinds of shellac? Now I feel bad for spilling the stuff.

Curtis Carving Spoons/Settee Class

by Elia Bizzarri | Apr 23, 2017 | 0 Comments

Curtis Buchanan and I spent some time carving spoons last January. I photographed his process, which he describes as “the way a chairmaker with bad elbows carves a spoon.” Or something like that.

He carves the bowl first. This is steam bent cherry. read more…

He carves the bowl first. This is steam bent cherry. read more…

Thanks Curtis

by Elia Bizzarri | Apr 2, 2017 | 0 Comments

I first met Curtis Buchanan 15 years ago this month. My father drove the five hours to Jonesborough, TN and dropped me, a 17-year-old homesick boy, off for a week.

I first met Curtis Buchanan 15 years ago this month. My father drove the five hours to Jonesborough, TN and dropped me, a 17-year-old homesick boy, off for a week.

Curtis had a student that week. I split logs and listened in on the class. I couldn’t imagine I would ever build a Windsor chair – they seemed so complicated. Curtis was the most welcoming woodworker I had ever met. I don’t think I realized it then, but Curtis was living my dream. “Maybe I can come back one day,” I said as I was leaving. “You’ll be back,” he replied.

Curtis taught me what I know about chairmaking. He also became a model for my life. I wanted to emulate his laid-back nature, his sociability, the conscious way he paced his life, his generosity. I think I even acquired some of his accent. Curtis is still one of the most remarkable men I have ever met.

Kiln Construction

by Elia Bizzarri | Mar 18, 2017 | 0 Comments

We have talked about kiln temperatures and kiln heaters, now onto kiln construction.

Curtis Buchanan’s kiln

Size

The primary use of a chairmaking kiln is to super-dry tenons. It’s nice to be able to set bends in a kiln too. This requires the kiln to be large enough to fit the bend while it’s in the bending form. Some bent parts have tenons, like a loop back bow, so ideally these tenons would be super-dried. My kiln is 2x2x3′ and that’s plenty big enough for two or three chairs worth of bends and other parts. Most folks can get by with something smaller. read more…

Subscribe to Elia's Blog

Recent Posts

Search the Blog

Donations

Donate below to help keep the blog going. Thanks!

Categories

- Chair Stories (32)

- Chairmaking Tools and Supplies (42)

- Chairs For Sale (5)

- Classes (58)

- Craft Films (43)

- How-To (40)

- Antique Chairs (8)

- Drill Bits (3)

- Spoon Bits (3)

- Finishing (9)

- No-Glue joints (2)

- Samuel Wing Book Project (10)

- Sprinpole Lathe (2)