All about Green Wood: Online Class #2

by Elia Bizzarri | Aug 9, 2020 | 5 Comments

Since my drawknife class last weekend, I have been running around buying new cameras, stand, cables and a wireless mic. I feel like it’s Christmas every time the mail lady comes. I found a new videographer (Roy Underhill is a little busy), and am working on ways to speed up my internet. I’m excited to put it all to use next weekend!

Since my drawknife class last weekend, I have been running around buying new cameras, stand, cables and a wireless mic. I feel like it’s Christmas every time the mail lady comes. I found a new videographer (Roy Underhill is a little busy), and am working on ways to speed up my internet. I’m excited to put it all to use next weekend!

I’m going to try a slightly different format for this second class. I’ll do a demonstration for the first 75 minutes or so, then we’ll have Q&A immediately following the demonstration. Let me know what you think!

GREEN WOOD

Buying (what to look for in a log)

Where to find Green Wood

Riving

Tools (how to buy froes and wedges that work)

Work Holding (breaks and other devices)

Can dry wood be made green again?

Myriad other bits of rare and priceless information

Saturday, August 15th, 1-3pm EST

Donations worked so well last time that I’m going to try it again for this class. Visit my online classes page to make a donation and register.

Space-Saving Shavehorses

by Elia Bizzarri | Aug 6, 2020 | 7 Comments

My first online class about drawknives was quite a success last weekend. Fifty-eight people registered for the class and Roy Underhill showed up with lots of equipment and proceeded to film the entire class for me. We had lots of good questions.

One question that came up was working wood without a shave horse. Shave horses do take up a lot of real estate in the shop. I hang my collection in an out door shed:

The horses hang from this little dowel in the front leg of the horse. There’s also a neat idea for a knock-down shavehorse.

Bob Simmons, who has taken three classes from me, sent these ideas for compact shave horses: In his words:

Some woodworkers want to shave with drawknife or spokeshave but have difficulty committing to a shaving horse to hold the work. The issue is usually floor space for storage. This simple pipe clamp, wooden block, lag screw device holds stock at convenient height for shaving while standing and allows the stock to be rotated. It does not work well when shaping chair spindles which are flexible since this device uses compressive forces and the spindles tend to buckle.

read more…

Drawknives: My first Online Class

by Elia Bizzarri | Jul 27, 2020 | 2 Comments

In the last three weeks, I have learned more about USB ports, bitrates and internet hotpsots than any chairmaker should ever know. Having tested everything to the best of my abilities, I am now ready to run my first class, this Saturday, August 1st, 1-3pm, with a follow-up Q&A session Sunday August 2nd, 3:30-5pm. Hopefully everyone will go into their shop after the first class, try what they’ve learned and then ask any follow up questions on Sunday.

Topics include:

Buying drawknives (what to look for: straight vs. curved, bevel up vs. bevel down, new vs. old…)

Sharpening (what angle to use, how to grind, how to hone, tightening handles, etc.)

Work Holding (shave horses, bench gizmos…)

Use (various projects, flattening a board, making round objects, )

Reading grain direction

Myriad other bits of rare and priceless information

This first class is available on a donation basis – spread the word!

For more info and to register, visit my Online Classes webpage.

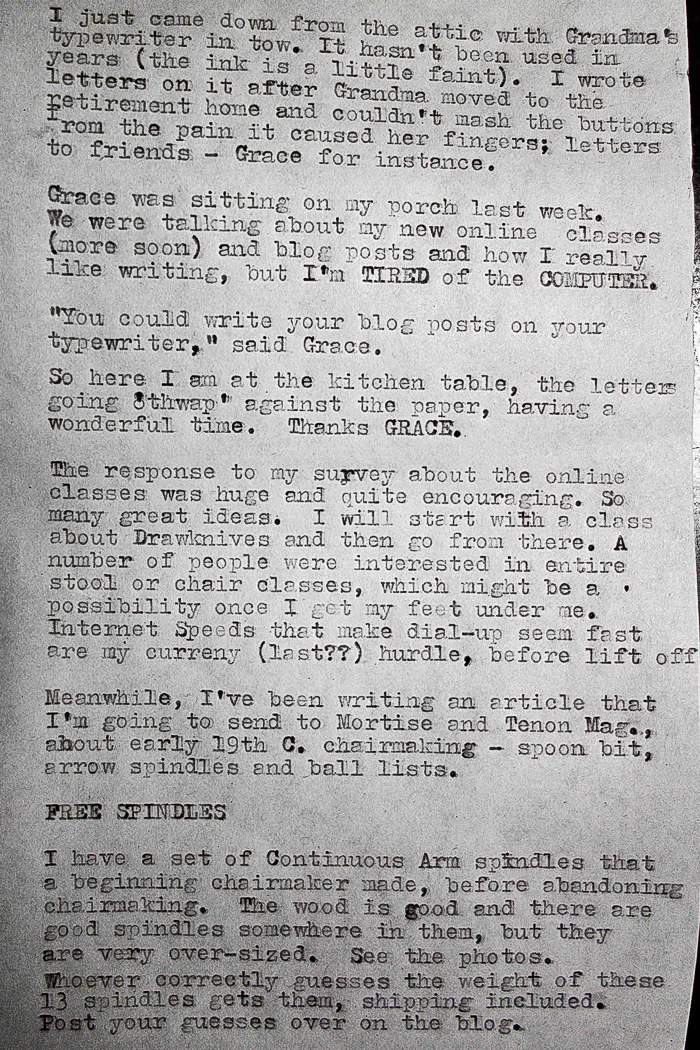

SPINDLE WINNER

The winner of the spindle giveaway was Mark Nicholson, who’s guess was a mere one ounce less than the correct weight of 2# 8oz. Congratulations!

Update and Free Spindles

by Elia Bizzarri | Jul 20, 2020 | 26 Comments

New Online Classes

by Elia Bizzarri | Jul 7, 2020 | 1 Comment

I miss this scene. A group of excited students show up on Monday morning and experience green wood for the first time. Like everyone else, my teaching has completely dried up. I’m lucky that I have a diverse means of income; tools and chair parts are selling better than ever, and I’ve even had a few orders for pitch forks and other fun projects. Plus I’ve had time to play around with a new tool that we may start making, a scraper for chair seats.

I miss this scene. A group of excited students show up on Monday morning and experience green wood for the first time. Like everyone else, my teaching has completely dried up. I’m lucky that I have a diverse means of income; tools and chair parts are selling better than ever, and I’ve even had a few orders for pitch forks and other fun projects. Plus I’ve had time to play around with a new tool that we may start making, a scraper for chair seats.

But I miss teaching. So I’ve decided to try a series of online classes. One of my students is a tech guy and he’s holding my hand as I figure this out. Our idea is that each class will be relatively cheap and comprised of two parts, each about two hours long. The first session will be a demonstration of skills and techniques (and maybe projects?), then you’ll have a chance to try what you learned in your own shop, then we’ll have a session to answer questions the next day. I’ve never done anything like this before, so I want to start with one class relatively soon, see how it goes, then tweak it from there. But what class should I do?

If this idea interests you, would you mind filling out this survey and helping me pick my first class. All ideas are welcome and encouraged. Many thanks!

Create your own user feedback survey

Reamer Giveaway

by Elia Bizzarri | Jun 30, 2020 | 7 Comments

The last few months have been a time of innovation for me. I’ve been working on a new tool to produce – a handled scraper for cleaning up chair seats. Right now I’m trying to bend the handles out of walnut, which isn’t real easy. I’ve also been working on new chair designs. And I added a removable handle to the reamers I make. Tim Manney’s excellent reamer has a removable handle, while mine has been made out of straight-grained dowels. But dowels aren’t all the same size, so fitting them was a pain, and the removable handle seemed like a nice touch. So now the handles are riven from a hickory log and turned to a 2 degree locking-taper on my patternmaker’s lathe.

I have one of the old dowel-handle reamers left over and I’d like to give it to someone who is serious about chairmaking, but might not be able to afford a reamer. Maybe a young person? If you know someone, nominate them in the comments section on the website. I’ll choose a winner this weekend.

Rewards of Repetition

by Seth Elliott | Jun 11, 2020 | 3 Comments

Elia recently invited me to contribute to his blog. By way of introduction, I’ve been working with Elia since 2017—primarily as resident toolmaker. Prior to that I had a career as a baker and pastry chef, but my shift to woodworking had earlier inklings. After college I apprenticed some with my father, a woodworker of nearly 50 years who has split his time between Windsor chairs and small wooden boats. And back in 2008 I traded work time for instruction from Elia as I built a fanback side chair for my daughter and later assisted his first class at The Woodwright’s School. read more…

Elia recently invited me to contribute to his blog. By way of introduction, I’ve been working with Elia since 2017—primarily as resident toolmaker. Prior to that I had a career as a baker and pastry chef, but my shift to woodworking had earlier inklings. After college I apprenticed some with my father, a woodworker of nearly 50 years who has split his time between Windsor chairs and small wooden boats. And back in 2008 I traded work time for instruction from Elia as I built a fanback side chair for my daughter and later assisted his first class at The Woodwright’s School. read more…

British Pathe

by Elia Bizzarri | May 3, 2020 | 0 Comments

For your entertainment and edification, here are some more British Pathe woodworking videos. If you watch one, watch the tennis rackets – it’s a pretty neat look at a mechanized shop that was still using a froe and drawknife.

Turners making chess pieces in Hungry in the 1960’s. They are flying, using a pretty big skew chisel.

Gramercy Spoon Bits – a review

by Elia Bizzarri | Apr 23, 2020 | 0 Comments

Last summer Gramercy sent me some of their new spoon bits to review here on the blog. I’ve never gotten free stuff from a company before, but I guess there’s a first for everything. Don’t worry, I’m still as opinionated as ever.

Anyway, the next thing I knew I was using them to build a copy of a writing arm chair that was in Colonial Williamsburg’s collection. Then I was using them at the January symposium. And then Fine Woodworking asked me to review them, which I just finished doing. So now I’m finally going to review them here, more thoroughly this time.

I have had the privileged of using a handful of antique smith-made spoon bits, and they are a joy. The cutting angles at the tip all seem to fall within a narrow range, and these cutting angles are critical to the bit’s speed. This is where most bits made in living memory fail.

Below are the four makes of spoon bits that I own. The straight-edge at the top of the photo is parallel with the cutting angle at the tip of each bit:

The Lore of the Spoon Bit

by Elia Bizzarri | Apr 15, 2020 | 7 Comments

How do you get a spoon bit to keep from wandering? What’s the best way to prevent tear-out with a spoon bit?

We are all victims of a post-industrial mindset and we all ask these questions. But these questions miss the point. Lets look at some photos of holes that were drilled by spoon bits in an early 19th C. chair writing arm chair in Colonial Williamsburg’s collection that I recently copied:

Subscribe to Elia's Blog

Recent Posts

Search the Blog

Donations

Donate below to help keep the blog going. Thanks!

Categories

- Chair Stories (32)

- Chairmaking Tools and Supplies (42)

- Chairs For Sale (5)

- Classes (58)

- Craft Films (43)

- How-To (40)

- Antique Chairs (8)

- Drill Bits (3)

- Spoon Bits (3)

- Finishing (9)

- No-Glue joints (2)

- Samuel Wing Book Project (10)

- Sprinpole Lathe (2)